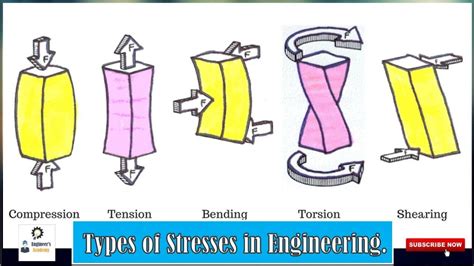

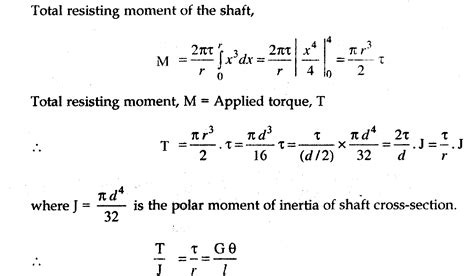

shear strain torsion test|how to calculate torsion : Chinese Method 1 involves calculating the shear stress present in the bar with an applied torque and then calculating the shear modulus by using the shear strain. The shear stress of the shaft is . Jogo do bicho - resultado do jogo do bicho - resultado da PT .

{plog:ftitle_list}

The latest tweets from @RubiRose

For point "a" on the cross-section, the shear stress on the x-face points in the positive z-direction. For point "b" on the cross-section, the shear stress on the x-face points in the negative y-direction. The corresponding stress elements for .Method 1 involves calculating the shear stress present in the bar with an applied torque and then calculating the shear modulus by using the shear strain. The shear stress of the shaft is .

Torsion testing predicts a material’s behavior under twisting forces by assessing key properties such as torsional strength, shear modulus, yield strength in torsion, ductility, and brittleness. It enables the understanding of fatigue behavior, .The strain energy per unit volume in a material subjected to elastic shearing stresses \(\tau\) and strains \(\gamma\) arising from simple torsion is: \[U^* = \int \tau d\gamma = \dfrac{1}{2} \tau .T=i(r F)(7) wherei isaunitvectoralongtheaxis.Theresult,atorqueortwistingmomentaround an axis, isascalar quantity. Example 2 Figure7:Workingonyourgoodoldcar-tryingtogetthesparkplugout.test specimen and calculating the slope of the shear stress versus shear strain curve. In addition, the torsion test specimen will be twisted to failure in order to determine the shear stress at .

During a torsion test, a specimen is subjected to a twisting or torsional force, which induces a torque. This test is used to measure various mechanical properties of materials, including their modulus of rigidity, shear stress, and .

Torsion Shear Test: This test involves applying a twisting force to a material until it fails. It’s useful for materials and components like shafts and fasteners that experience torsional stresses in their applications. Punch Shear Test: Also .

PROCEDURE. Measure the diameter (D=2R) of the gage section for each specimen to 0.02 mm. Install the bottom end of the torsion specimen in the lower grip of the test machine. Rotate the lever arm as far to the right as possible. . Torsion testing involves the twisting of a sample along an axis and is a useful test for acquiring information like torsional shear stress, maximum torque, shear modulus, and . State of stress and strain in torsion. Shear strain and its relation with angle of twist. . A torsion test has the following advantages over the tension test. A shear stress–strain diagram determined from torsion test is fundamentally more important in characterizing the plastic behaviour of material than a conventional or a true stress .

Torsion tests twist a material or test component to a specified degree, with a specified force, or until the material fails in torsion. The twisting force of a torsion test is applied to the test sample by anchoring one end so that it cannot move . The shear strain is defined to be the ratio of the horizontal displacement to the height of the block, \begin{equation}\alpha=\frac{\delta x}{h}\end{equation} For many materials, when the shear stress is sufficiently small, experiment shows that a Hooke’s Law relationship holds in that the shear stress is proportional to shear strain,

A modified Nadai's method is proposed to determine the shear stress-strain curve by use of a solid circular cylinder subjected to torsional load. The modification is accomplished by taking into account the axial length change of the specimen. The method is extended to give the shear stresses in tubular specimens. A series of experiments on annealed isotropic high purity cast .

Abstract. A modified Nadai's method is proposed to determine the shear stress-strain curve by use of a solid circular cylinder subjected to torsional load. The modification is accomplished by taking into account the axial length change of the specimen. The method is extended to give the shear stresses in tubular specimens.A series of experiments on annealed isotropic high purity .What was the effective strain during the torsion test? The only strain induced during the torsion test was the true shear strain γxy ~ . No other strains were present: 0~ = ~ = ~ = ~ = ~ = εx εy εz γyz γzx Substituting these conditions into Eq (8), we find: ε γ~ xy 3 1 = .. during the torsion test the effective strain (ε) equaled the .

A cable torsion test involves subjecting a cable to twisting forces to evaluate its performance and reliability. This test is crucial for industries such as aerospace, automotive, and construction, where cables are used in critical applications. . Torsion testing allows for the accurate measurement of shear stress and strain, which are . For the second method for determining the strain from the in-plane torsion test, the torque M and the rotation angle α are continuously measured in order to analytically calculate model parameters or shear stress-strain curves based thereon. This method is based on the assumption that the properties of the tested materials are isotropic and rate-independent.

SHEAR AND TORSION David Roylance Department of Materials Science and Engineering Massachusetts Institute of Technology Cambridge, MA 02139 June 23, 2000Strain is what results from this stress. Strain, ε, is defined as the change in length divided by the original length, ε = Δ I / I o. Before we proceed further with stress and strain, let's define some other types of stress. If instead of pulling on our material, we push or compress our cylinder we are introducing compressive stress. This is .

torsional stress vs shear

•Shear strain: •Shear modulus relates shear stress and strain: •Calculate shear modulus from Eand ν: •Direct shear: shear forces without bending moments or normal forces •Single vs. double shear •Pre-week videos: design of deformable materials, general states of stress, and axial deformation 12 W ave VA 2 *SHEAR AND TORSION David Roylance Department of Materials Science and Engineering Massachusetts Institute of Technology Cambridge, MA 02139 June 23, 2000Torsional shear stress solved examples: 1] The shaft of the motor is rotating with a maximum torque of 6 N.m. If the shaft has a diameter of 25 mm, find the maximum shear stress acting onto the shaft.The relation between shear strain and shear stress is . 𝜏 is the shear stress and G the modulus of rigidity. G is one of the elastic constants of a material. . IS 1717 (2012): Metallic Materials - Wire - Simple Torsion Test, Third Revision, 2012; Community Links Sakshat Portal Outreach Portal FAQ: Virtual Labs. Contact Us Phone: General .

m) or foot-pound force (ftshear stress at which the plastic component of shear strain, due to torsion at the test piece outer surface, is equal to a specified percentage. Note 1 to entry: A suffix is added to the subscript to indicate the prescribed percentage, e.g. . .Torsion Formula: Shear Stress • From Hook’s law for shear, if the material behavior is linear-elastic then a linear variation in shear strain leads to linear variation in shear stress. So the shear stress for a solid shaft will vary from zero at the shafts longitudinal axis to a maximum value τmax at its outer surface such that: τmax ρ τStrain display Torsion Test Device Main frame Torsion test specimen (bar) with installed strain gauges Loading arm, hanger and weights Strain display. 9/29/2011 9 . • Plot the five points and compute the shear modulus, G, using a best-fit straight line. 9/29/2011 10 .

Therefore, strain is a dimensionless number. Strain under a tensile stress is called tensile strain, strain under bulk stress is called bulk strain (or volume strain), and that caused by shear stress is called shear strain. The greater the stress, the greater the strain; however, the relation between strain and stress does not need to be linear.In particular, the results from the torsion test will be compared to the results of the engineering tensile test for a particular alloy using the effective stress-effective strain concept. EQUIPMENT • Constant-diameter gage section torsion specimen of 6061-T6 aluminum • Torsion test machine with grips, troptometer, and force sensor. PROCEDURE2. Compute shear stress, , and shear strain, . Plot also - curve. 3. From the data obtained, determine the following properties for the specimen. a. Torsional Stress and strain (eqns 5 and 6) b. Shear Modulus (eqn. 7) c. Shear stress at proportional limit (from the shear stress- shear strain plot) d. Modulus of Resilience (eqn. 8) e.

custom non contact building moisture meter

Type initial data into the torsion test program (figure 1.2.3). Click Run. Figure 1.2.3. Screenshot of program. 6. Set speed to ~ 5°/min, zero the torque and start test (figure 1.2.4). . • For each measurement of torque and angle of twist, the shear stress and shear strain are calculated. Tr .Shear Strain: Dr. M. Medraj 4 Torsion Test • Not as common in testing as tensile test. • Torsion test samples (similar to tensile samples). • But also used on full sized parts such as shafts, axles, drills etc. Troptometer Torsion machine • Torsion machines use an electrical motor and gear drive to apply a torque to the specimenOn the same graph, plot shear stress, , and engineering shear strain, as functions of radial distance, r, at 30° of rotation. . The shear modulus, G, from the torsion test can now be calculated from the relation: (N/mm2=MPa) 4. Finally, record the measured torques and calculate for = 90° and 360°.

For example, Fig. 6(b) shows the shear strain vs time for three different tests, the average shear strain rate is evaluated by taking the slope of the linear fit line of shear strain and time and it is derived for each test. The average strain rate values obtained from these experimental tests lie in the range of intermediate strain rates. Background Using a thin-walled tube torsion test to characterize a material’s shear response is a well-known technique; however, the thin walled specimen tends to buckle before reaching large shear deformation and failure. An alternative technique is the surface stress method (Nadai 1950; Wu et al. J Test Eval 20:396–402, 1992), which derives a shear .Torsion tests can be performed by applying only a rotational motion or by applying both axial (tension or compression) and torsional forces. Types of torsion testing vary from product to product but can usually be classified as failure, proof, or product operation testing. Torsion Only: Applying only torsional loads to the test specimen.

custom non contact moisture meter price

Resultado da KOCOWA+ is THE Ultimate Destination for Korean Entertainment 25,000 + HOURS OF EXCLUSIVE SHOWSWatch shows the same day they air in .

shear strain torsion test|how to calculate torsion